Introduction to General Settings in Main Window

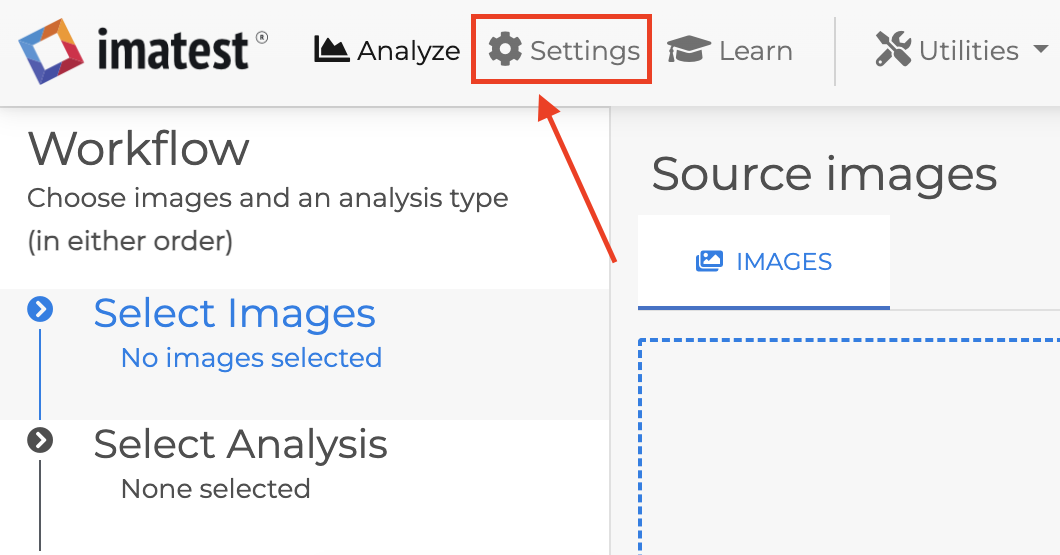

To go to General Settings page, click on Settings at the top of the Main Window.

|

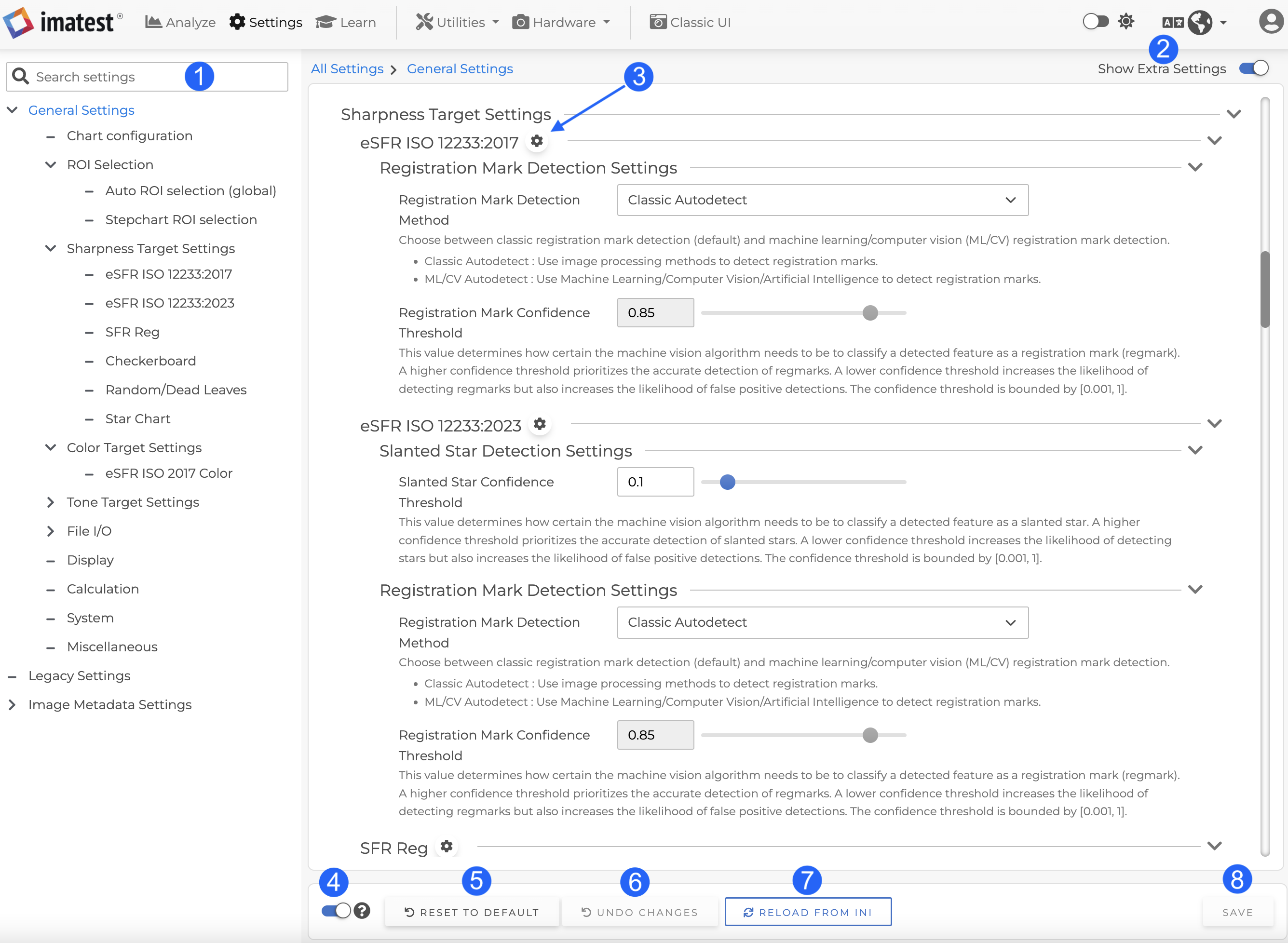

1 |

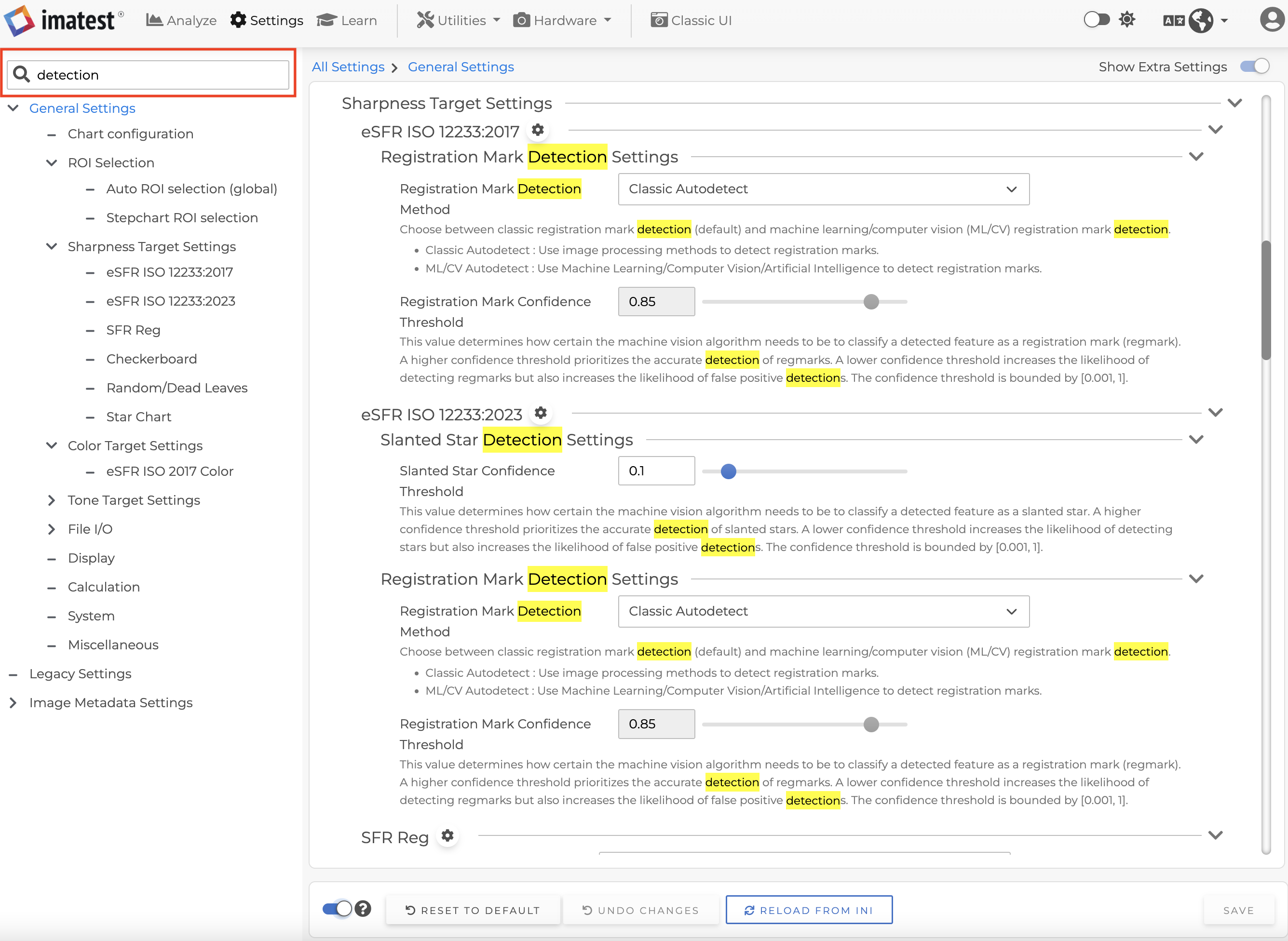

Search field |

The search field is only available for General Settings and will search globally throughout general settings. After typing in the search box, only matched settings will be shown, and the search term will be highlighted in yellow. It will search category names, descriptions and option labels. |  |

|

2 |

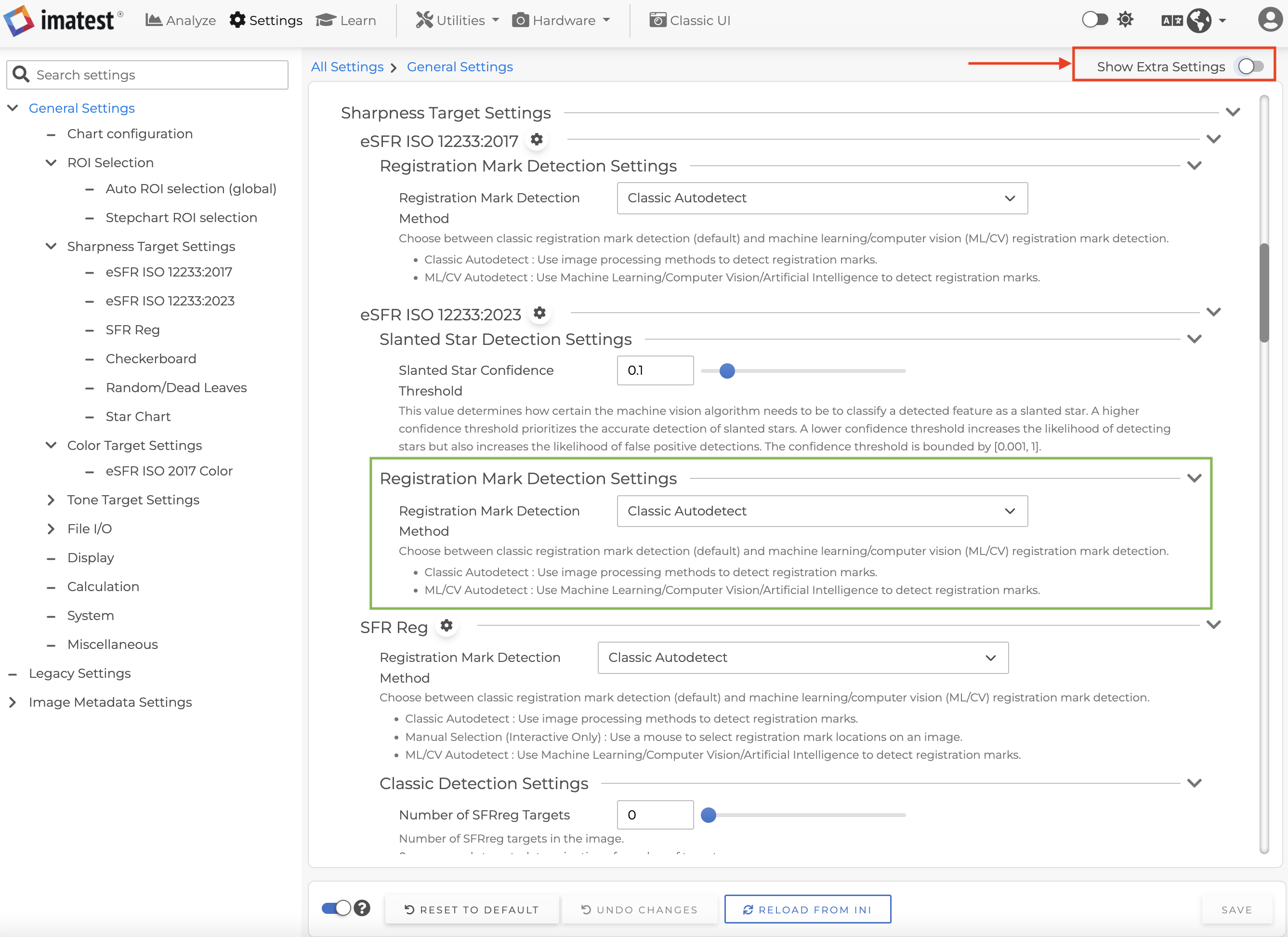

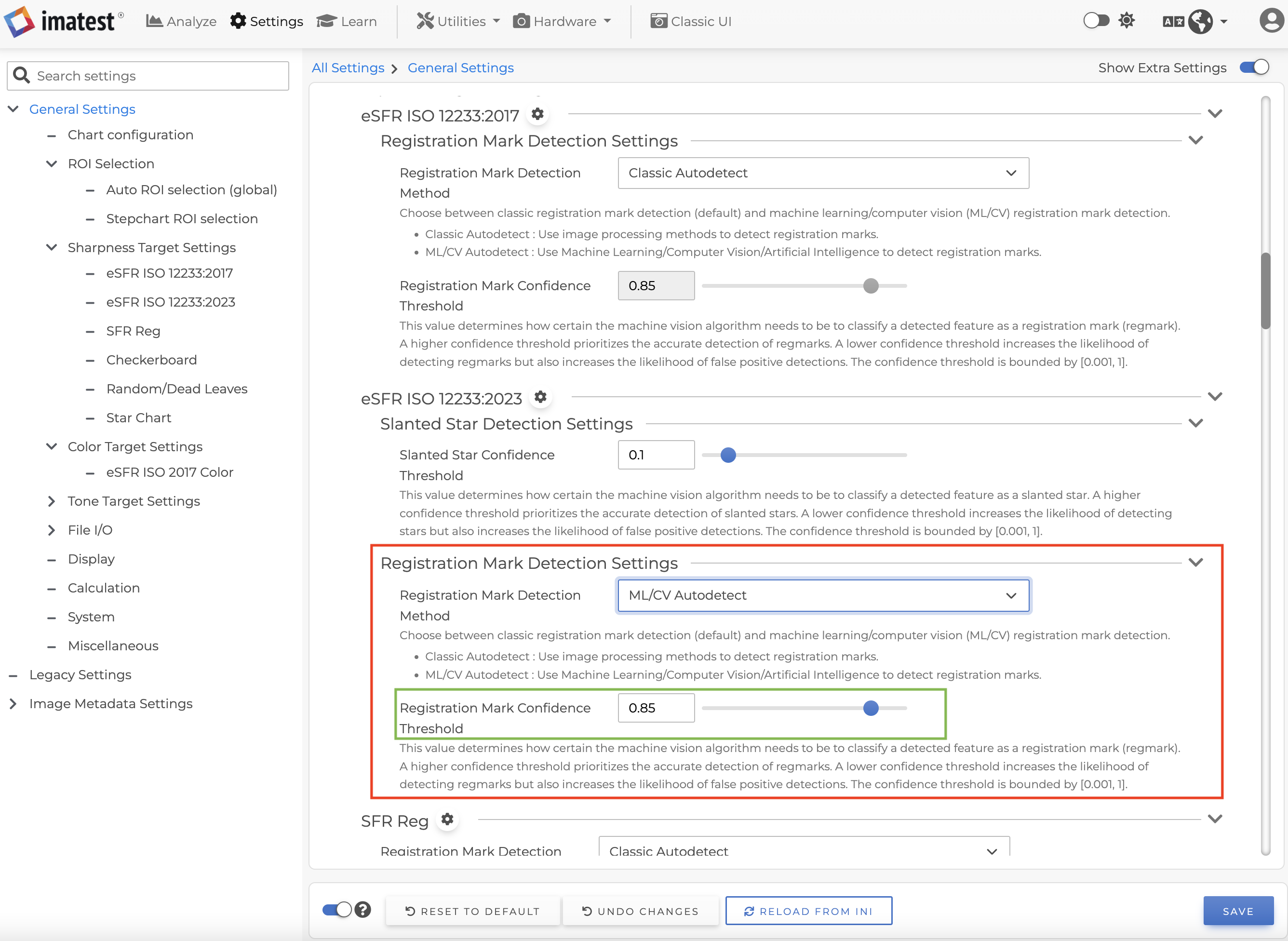

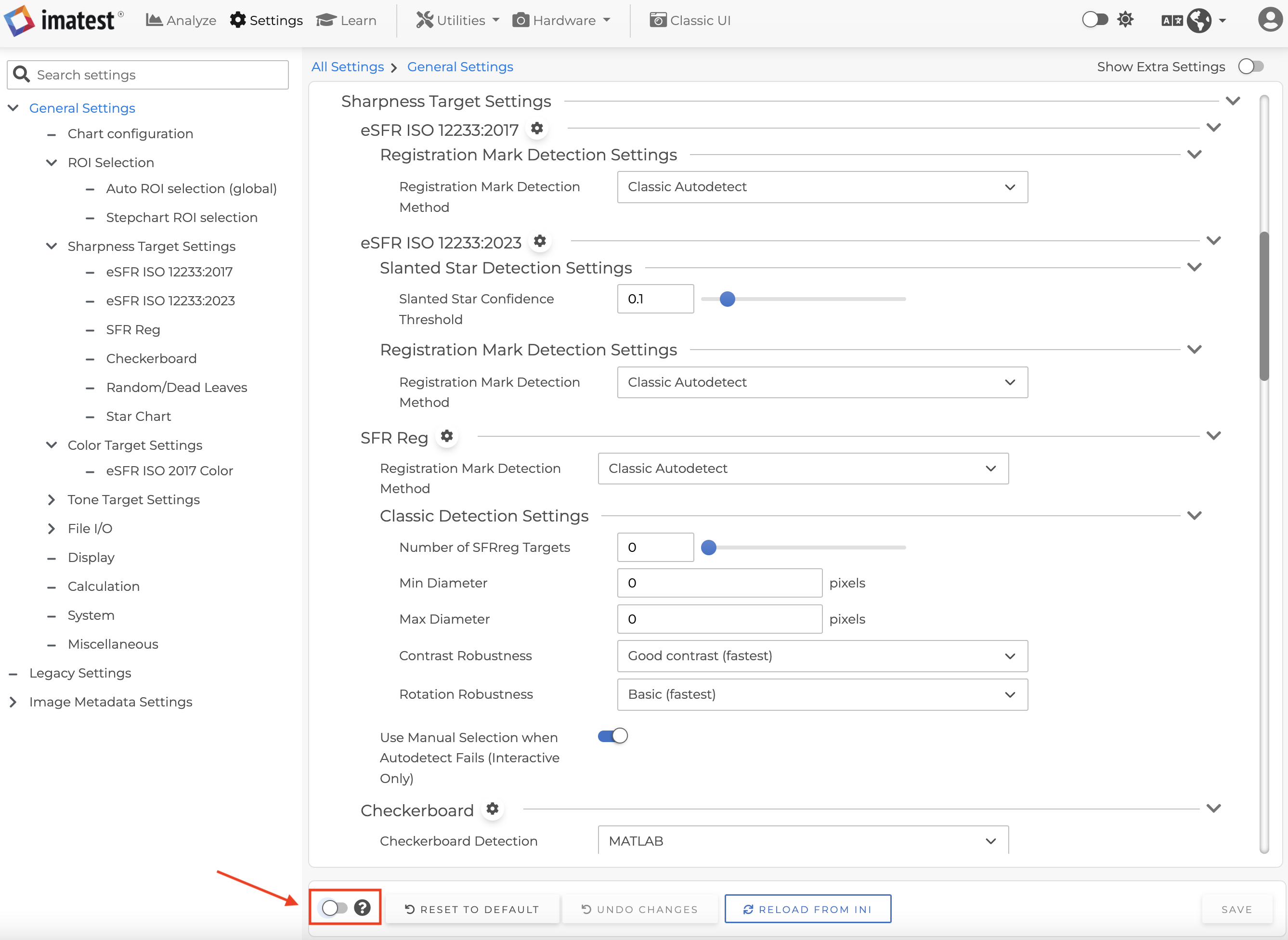

Show/Hide Extra settings |

Some settings are not applicable based on the value of other settings. When the “Show Extra Settings” toggle switch is on, the settings that are not applicable will be shown, but disabled. When the “Show Extra Settings” toggle switch is off, the settings that are not applicable will be hidden. For example, the first image shows that the “Show Extra Settings” toggle switch is off and the “Registration Mark Confidence” has been hidden because that setting does not apply when “Registration Mark Detection Method” is “Classic Autodetect”. Once the “Registration Mark Detection Method” has been changed to “ML/CV Autodetect” as shown in the second image, the “Registration Mark Confidence” can then be changed. |

|

|

3 |

Classic UI Settings |

Clicking on the Classic UI settings gear icon will open additional settings windows. Please note that while Classic UI windows are open, the “Reset To Default“, “Reload From INI” and “Save” buttons will be disabled until the window has been closed. |

|

|

4 |

Show/Hide Descriptions |

This toggle switch controls whether settings’ detailed descriptions are shown. |  |

|

5 |

Reset To Default |

This option is used to reset settings back to their original defaults. Note that only the settings that are currently visible will be reset. This is a different behavior from the “Reset to Defaults” function in the “INI” menu, which will reset your entire INI file. | |

|

6 |

Undo Changes |

When the settings have been changed locally before saving to an INI file, clicking on the “Undo Changes” button can reset all those settings back to their original state. | |

|

7 |

Reload From INI |

This option will reload setting values from the INI file. Sometimes, some settings have been changed from Classic UI or directly from INI file. Clicking on the “Reload From INI” button will ensure you have the latest changes on the General Settings page. |

|

|

8 |

Save |

After making changes to the settings, click the “Save” button to save those settings to the INI file. |