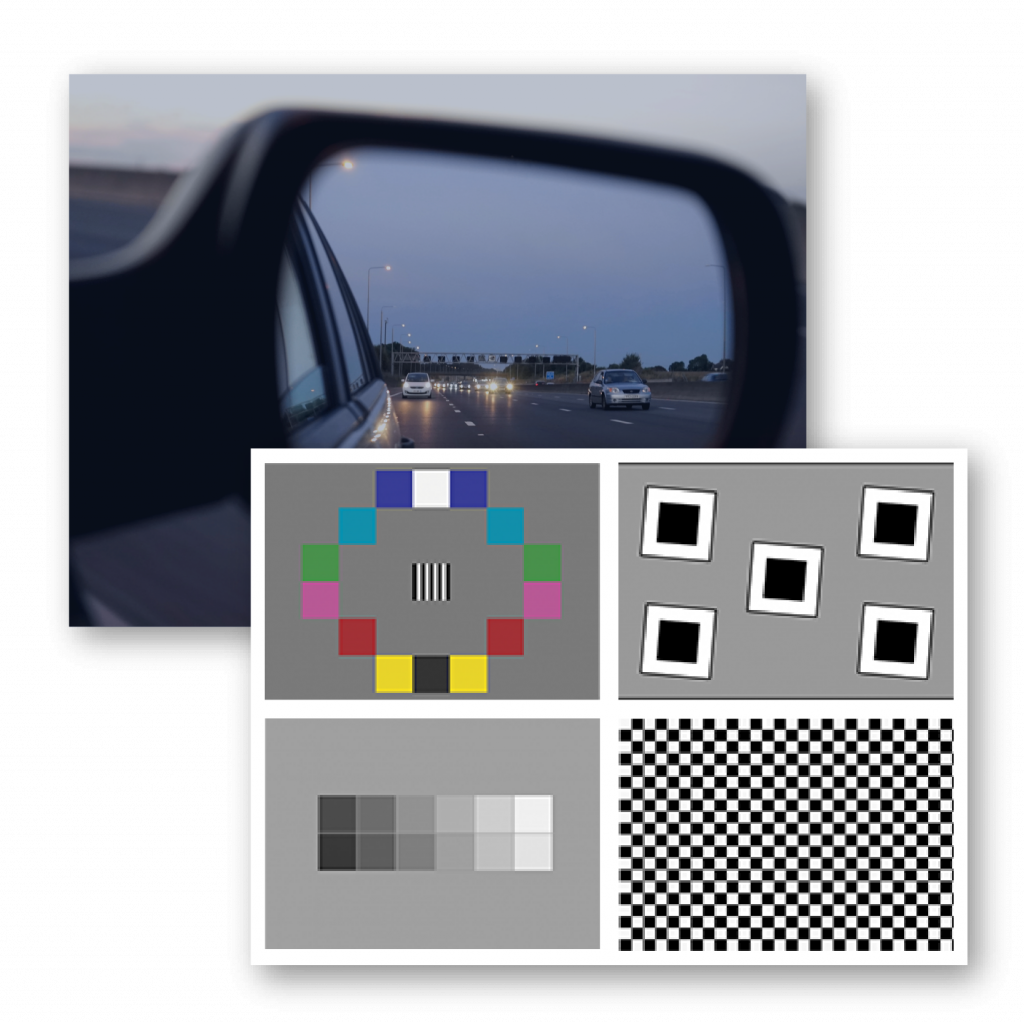

With the increasing number of automobile camera system applications such as Advanced Driver Assist Systems and Mirror Replacements, the automotive industry has to test and meet a wide variety of image quality standards. Factors to test include dynamic range, long range focus, contrast resolution, flicker, flare, and sharpness. We can provide the necessary solutions, including charts, equipment, and software to test these factors.

We also understand that not everyone’s testing needs are the same. That is why we are always standing by to help you design the solution that is best for you.

Advanced Driver Assist Systems (ADAS)

ADAS systems typically contain forward facing camera systems that rapidly analyze oncoming and nearby objects. The lenses on these cameras focus at a long-range to maximize the sensitivity of the system. Unfortunately, this complicates the testing process generally because of the limitations in lab size. Specialized equipment is therefore required to test the image quality at the needed distances.Our solution includes the necessary charts, equipment, and software to optimize your testing environment; including collimating relay lenses to project a high-resolution image at a virtual distance.

Key image quality factors to be tested include:

We are members of IEEE P2020, which started work in 2016 with the goal of pioneering new standards for ADAS key performance indicators, including contrast detection probability and flicker.

Rear View and Surround View Camera Systems

Rearview cameras typically have significant fisheye distortion and a Field of View (FoV) greater than 160°. Surround-view camera systems build upon the rearview camera system by adding side and front cameras. Using lens distortion correction, perspective transformation, and color correction algorithms, the systems can seamlessly integrate all camera images together for a 360° image of the vehicle’s surroundings.Special equipment and charts, are needed to accommodate the wide field of views of these systems. We offer these products including the Modular Test Stand Reflective WFoV Module, and pre-distorted SFRplus charts.

Key image quality factors and features to be tested include:

Mirror Replacement/Camera Monitor Systems (CMS)

Camera Monitor Systems are challenging to test because several factors in the multi-camera, multi-step process need to be set up correctly. Though the majority of the image quality factors are important, sharpness, contrast resolution, and color accuracy are of the highest importance.Our solution supports the ISO 16505 test charts and measurements and also offers several improvements to the standard.

Key image quality factors to be tested include:

Driver Monitoring Systems (DMS)

Driver Monitoring Systems (DMS) are designed to quickly analyze the driver’s face and eye position to determine their attention to the road in front of them. In order to provide accurate warnings to drowsy or distracted drivers, these monitoring systems require high-precision imaging to follow the driver in different light environments. In addition, the systems will be required to determine the activities of the driver, such as holding a phone(s), smoking, or other distractions. For example, Euro NCAP will, for the first time, start assessing direct driver state monitoring systems, as part of its 5-star rating program. Using our unique charts and our industry-leading software, you can ensure your cameras will have the necessary quality for your computer vision algorithms to perform optimally.Using our unique charts and our industry-leading software, you can ensure your cameras will have the necessary quality for your computer vision algorithms to perform optimally.

Key image quality factors to be tested include: