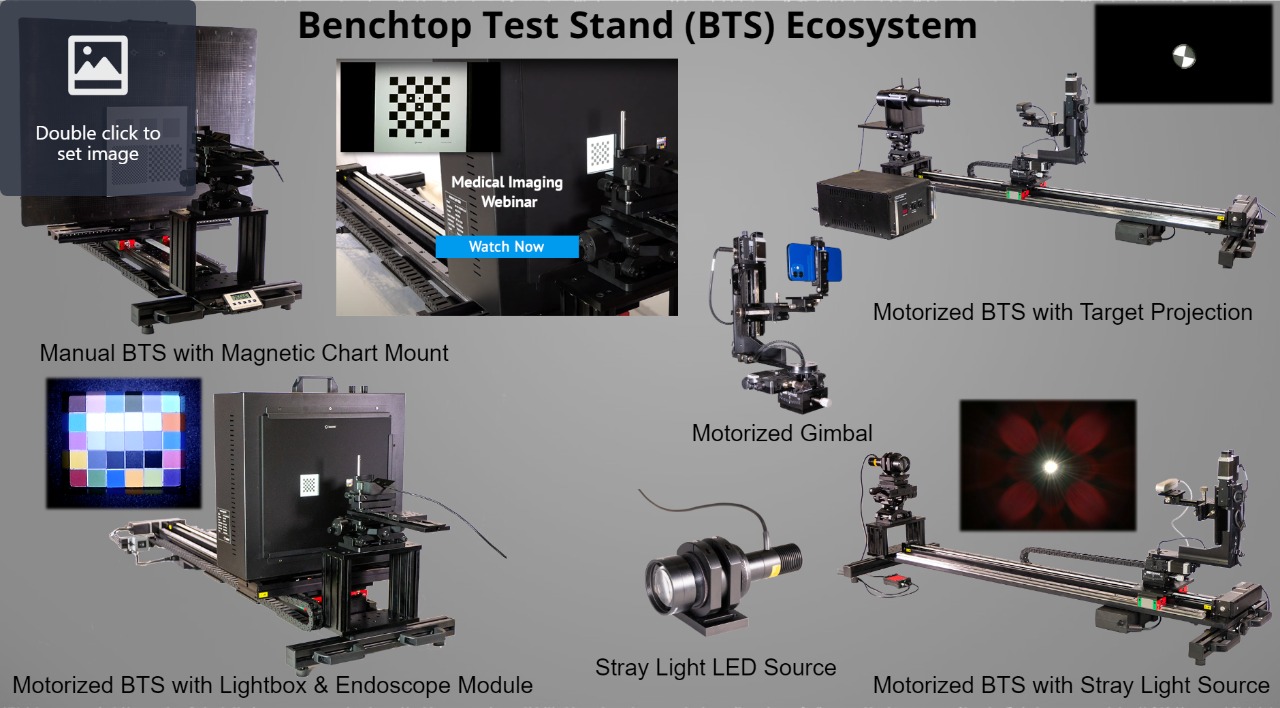

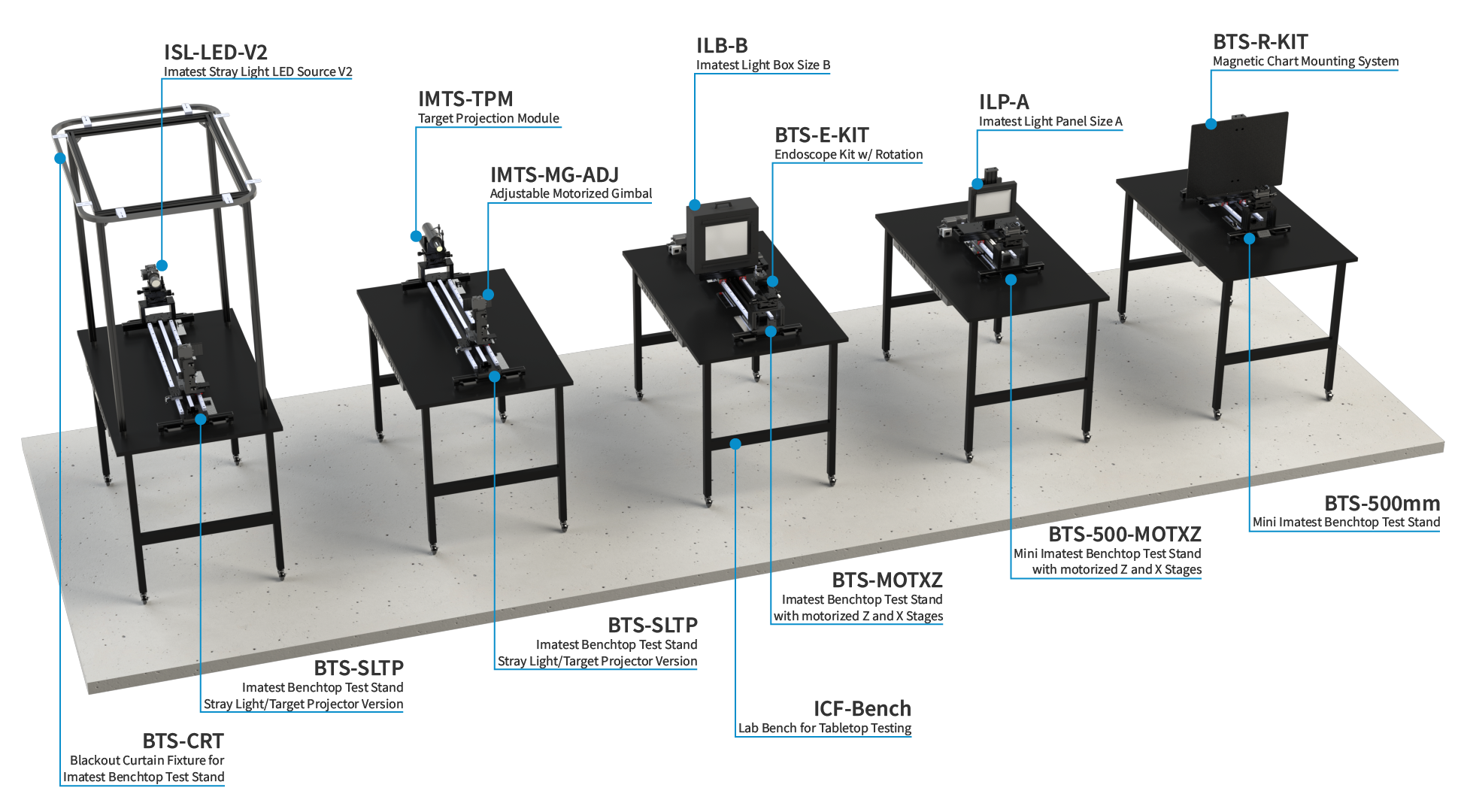

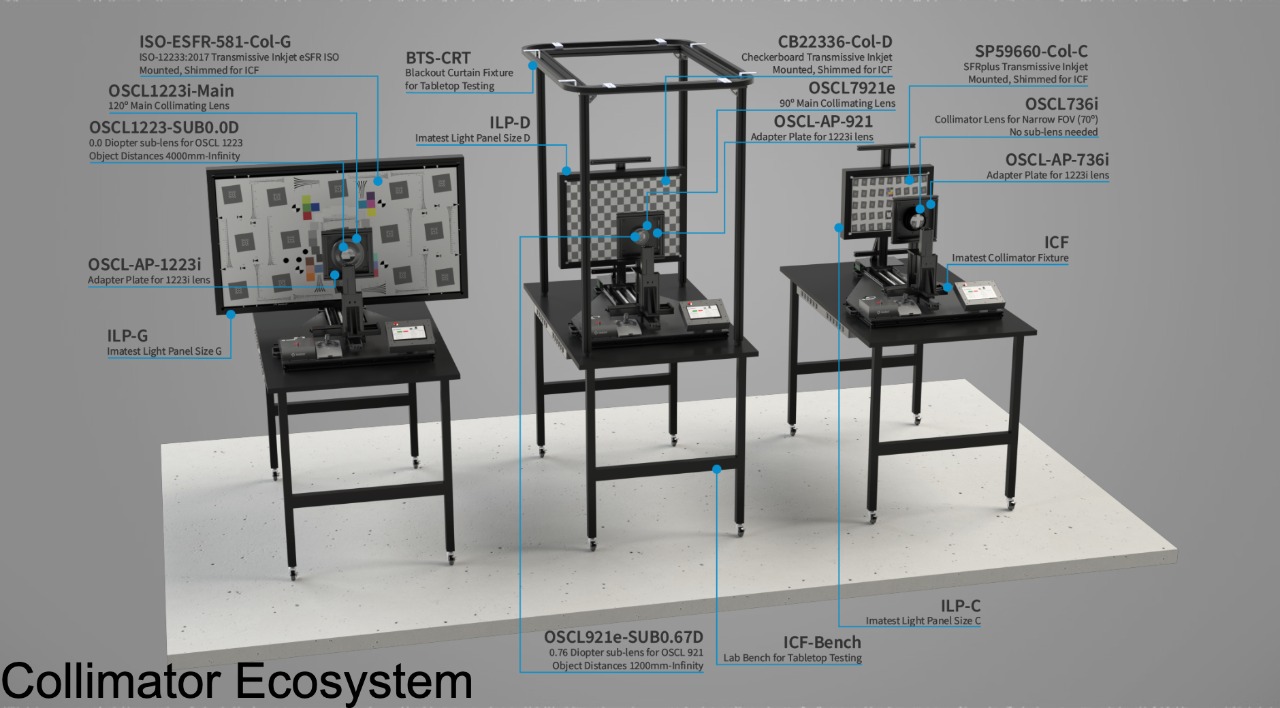

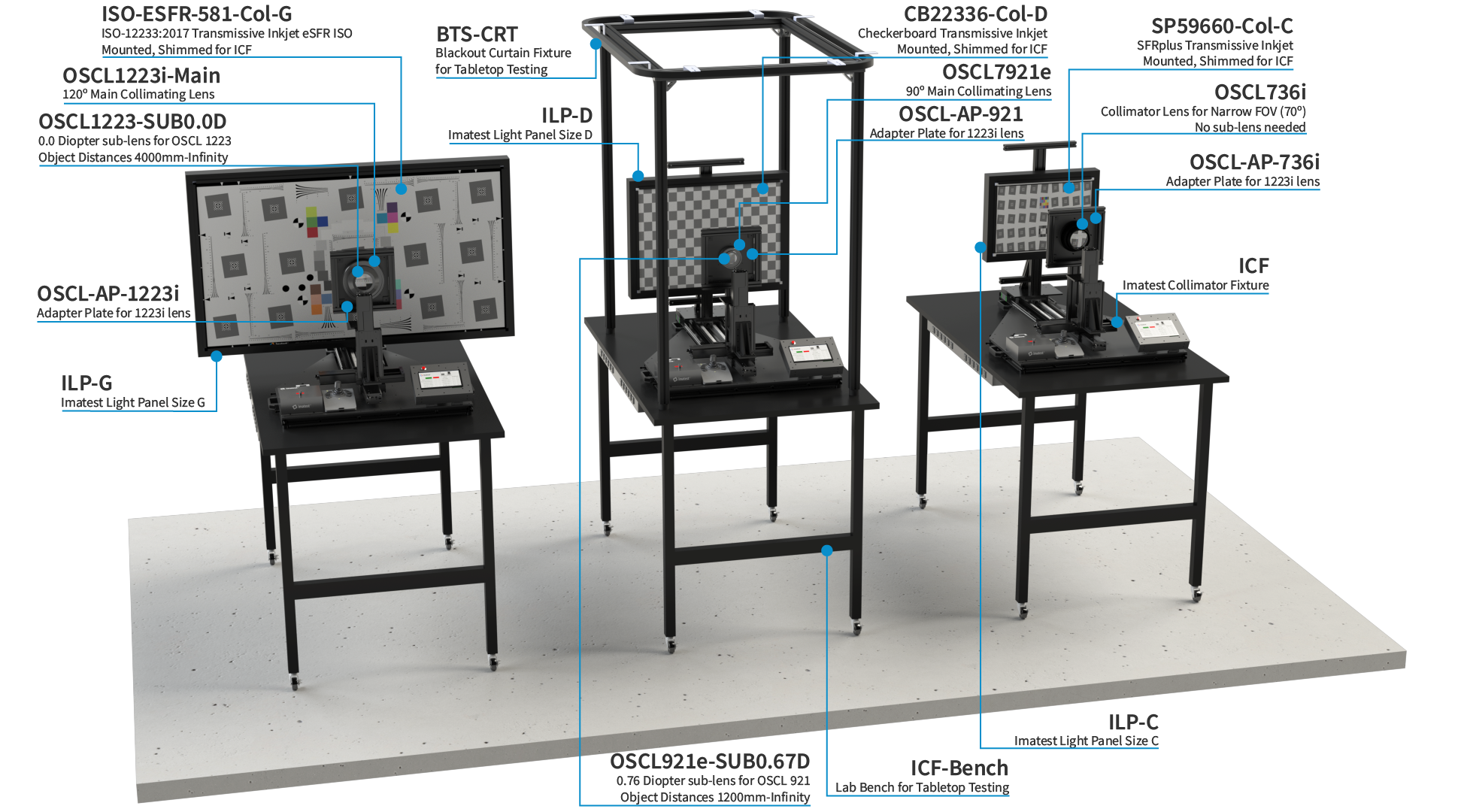

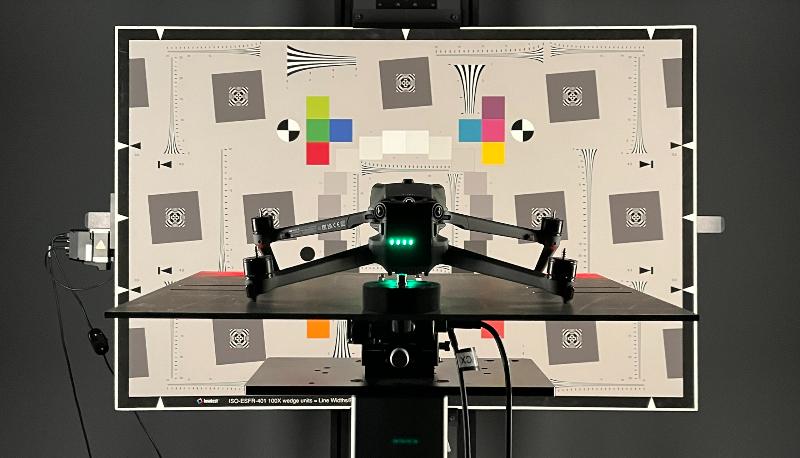

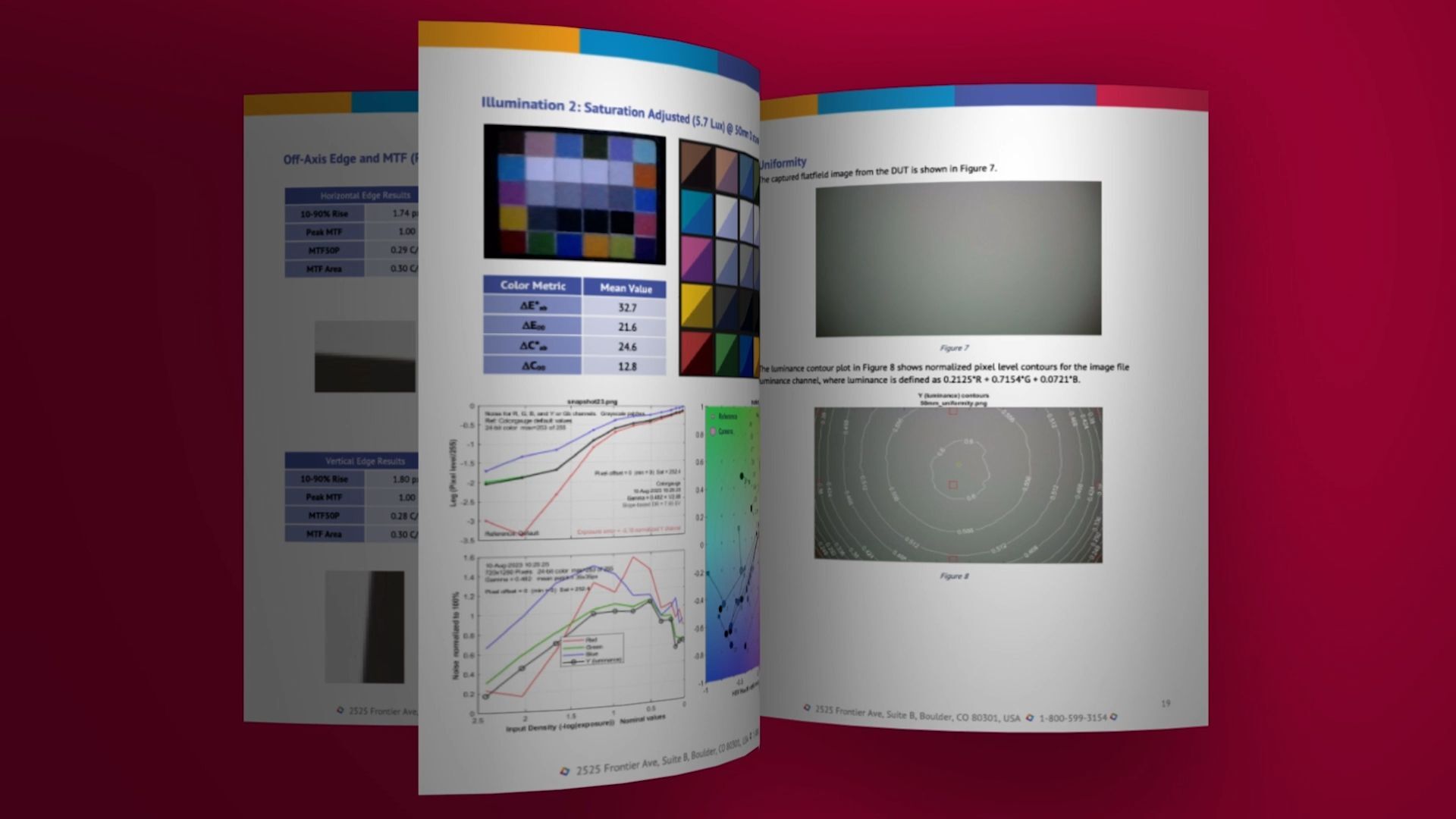

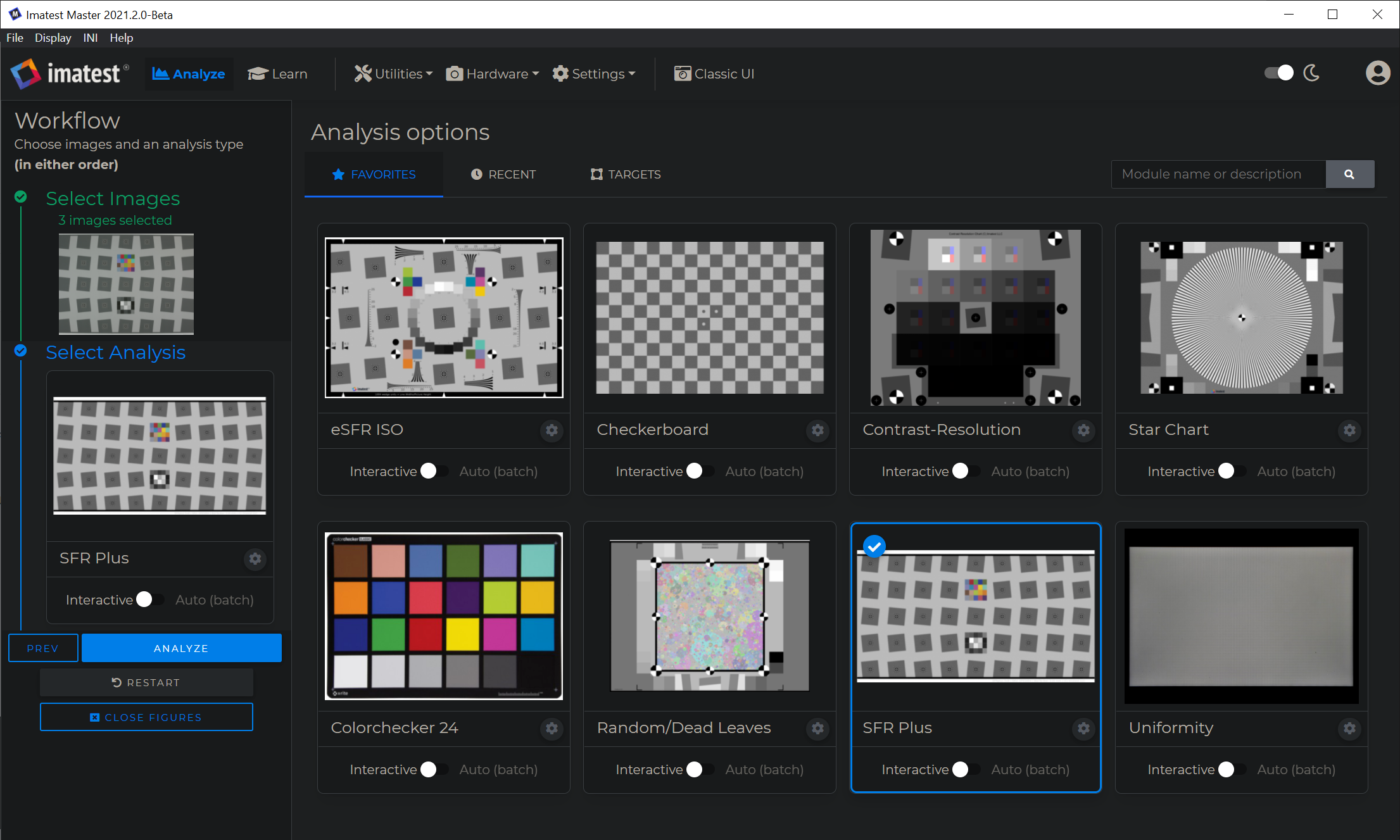

Imatest provides customers with software, charts and equipment to meet and exceed image quality testing standards.

Imatest gives companies the right tools to test their image capture technology and has been a leader in image quality testing for over 20 years. Whether it’s still shots or video, visible light or infrared, Imatest has helped businesses in a variety of industries, including mobile, automotive, medical and manufacturing.