Produce the Best Quality Images

In 2017, there were over 1.2 trillion photos taken with consumer electronics. Smartphones accounted for 85% of that. Do you have the right camera testing solution to ensure you have the best image quality?

Image Quality Standards

Experts at Imatest are actively involved in several standards committees, including the International Standards Organization (ISO) which works to agree on metrics and procedures for characterizing all sorts of devices, and the mobile-focused IEEE p1858 Camera Phone Image Quality (CPIQ) standard includes metrics which correlate with subjective perception.CPIQ v1 includes:

Important Test Considerations

It is imperative to test in a lab that can reproduce the wide range of environmental conditions in which mobile devices are used. Because of the complexity of real-life settings, this brings unique challenges that need consideration when testing.A few of the challenges you face include:

- testing the resolution and auto-focus for macro to long-range distances

- testing the contrast resolution and dynamic range for high to low-light scenarios

- testing image stabilization for hand to object movements

Imatest offers the solutions you need to achieve the best quality in each environment.

Maintain Quality Through the Manufacturing Process

Your reputation and the quality of your camera depend on maintaining high-quality test results throughout your supply chain. We work with test-equipment makers who can provide turnkey solutions that include our charts and software. Imatest IT, our manufacturing automation software, works seamlessly with Imatest Master, to ensure you make the right yield/quality trade-off.There are many challenges that come with high volume manufacturing of which we outline in our "Managing Supply Chain Image Quality” paper.

We offer a software version, Imatest IT, that is used for measuring image quality in the manufacturing process.

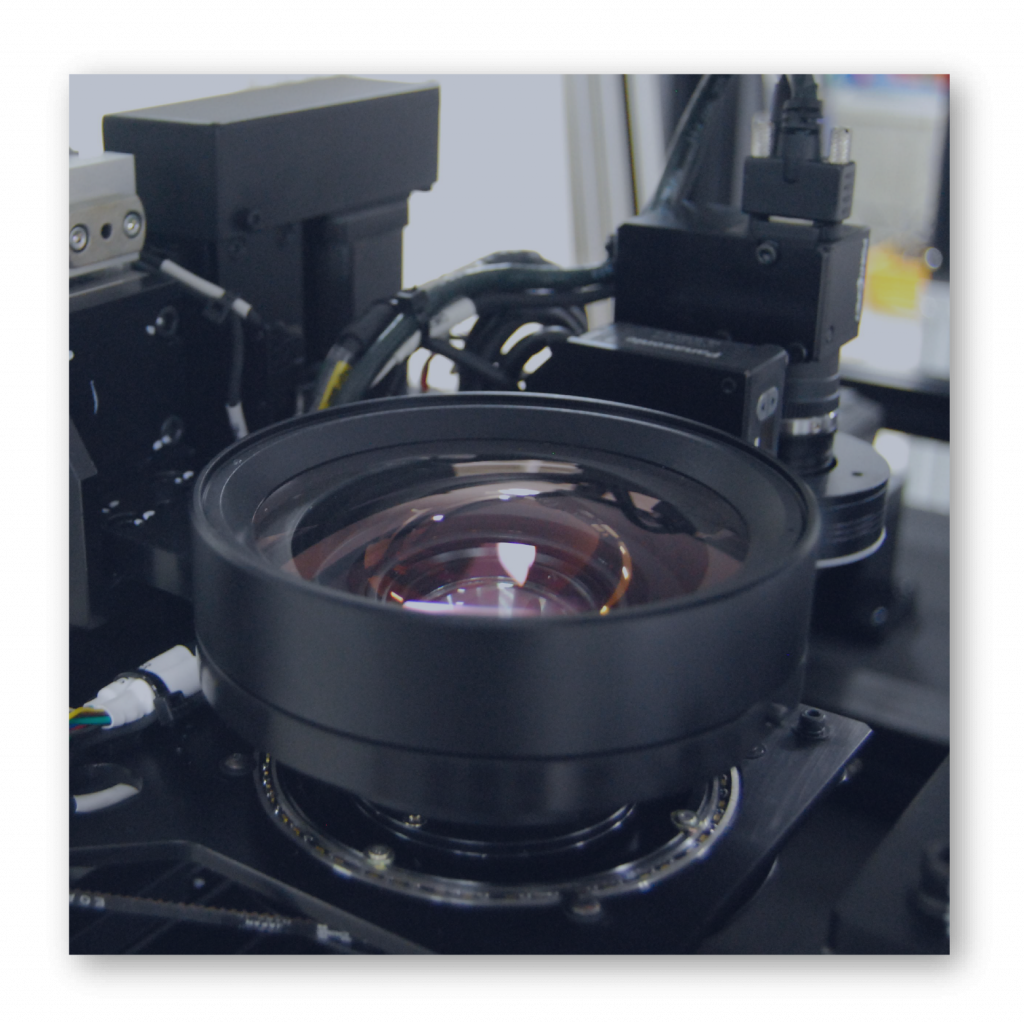

Testing Compact Camera Modules

A compact camera module (CCM) contains a lens and sensor integrated into a housing with a flex cable connection installed inside a mobile device such as a smartphone or tablet. These come in fixed focus and autofocus varieties. Typically the rear facing camera (RFC) has autofocus, while the front-facing camera (FFC) is fixed focus.As these devices come in very small form factors, the quality of the components and precision of the manufacturing is critical to their ability to achieve acceptable image quality. Testing at a macro distance and long-range is necessary to ensure that the optomechanical design is functioning adequately.

Imatest can help make sure you have the right solution to test your compact camera modules.

Consumer Camera Webinar

In this webinar, you will receive:- An overview of CPIQ definitions, references and more

- CPIQ test conditions and apparatus

- A description of image quality measurements including Spatial Frequency Response, Lateral Chromatic Displacement, Chroma Levels and more