Geometric camera calibration, also known as camera intrinsics calibration or multi-camera calibration, is the process of estimating the parameters required to relate (2D) points in a camera’s image plane with (3D) points in the world scene the camera is viewing. With a calibrated camera, each point on a sensor translates into a ray emanating into the scene, providing directional information about points in a scene.

With a pair of calibrated cameras (typically called a stereo pair), it is possible to triangulate distances and make estimations of the distance to points in the world. Determining geometry from multiple views (either from multiple cameras or multiple frames from one) is at the heart of classical computer vision.

Geometrically calibrating a device is not as simple as analyzing an image of a checkerboard pattern. It requires prior information about the nominal device specifications and lab setup requirements for the device you are testing. Imatest has the tools and the expertise to guide you through the whole process.

Calibration Test Machines

The Imatest-Furonteer Geometric Calibration Solution enables companies to better understand the images they capture from their devices. It calibrates as-built camera systems by accurately mapping the pixel position to real-world positions for monocam, stereo pair, and multicamera devices. We combine the analysis software and calibration hardware required for rapid testing in a production-line clean room. Imatest and Furonteer engineers optimize each test setup for your specific camera(s), and actuators enable automated camera manipulation to calibrate camera systems. Our engineers have successfully produced a high-throughput solution for devices between 28° and 155° field of view. Talk to our engineers to learn more about this solution.

Imatest-Furonteer Calibration Machine

Imatest-Furonteer Calibration Machine

The Importance of Target Setup for Geometric Calibration

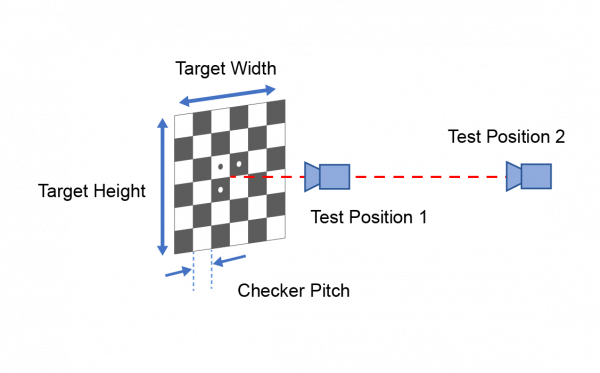

The setup is the most important part of the process. You will not have accurate and consistent results if you do not properly set up your lab and acquire the right requirements and specifications before analysis. Before beginning, make sure you:

- Determine your accuracy requirement for the parameters to be calibrated.

- Gather the nominal device specification values for your system, including the field of view for all devices, focal length, entrance pupil location, and sensor pitch.

- Understand the Required Evidence for calibrating a system, how the Calibration Procedure will make use of it, and how the evidence required relates to your requirements.

- Decide upon a Supported Target configuration based on your device(s’) parameters and the space allotted by your Test Setup.

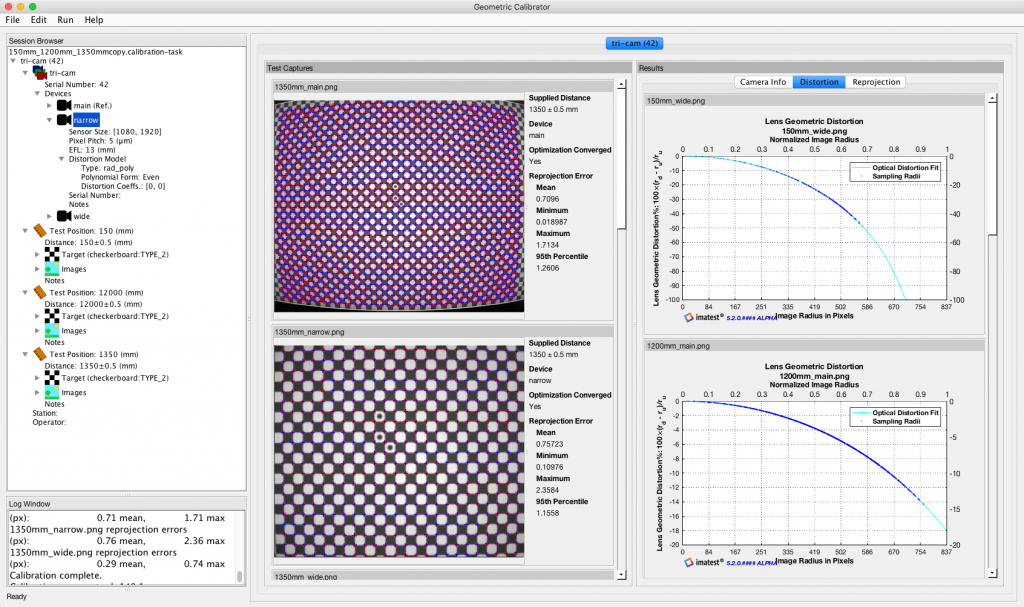

Imatest Geometric Camera Calibrator

Imatest-Furonteer’s total solution can provide geometric calibration estimations for both individual and multi-camera systems with narrow and wide-field-of-view camera classes. Imatest supports wide FoV cameras up to 155 degrees, heterogenous camera system (e.g. simultaneous narrow and wide FoV), novel censor CFA designs and novel distortion models. The system can track changes in quality over time by using different calibration values between build batches. Imatest acquires evidence from a planar checkboard chart. Using the evidence from the chart, with data about the device specifications and lab setup, Imatest can produce consistent and accurate calibrations even for challenging devices in a constrained setting (such as a production line).

Work With Imatest for Your Geometric Calibration

Our Geometric Calibration is not an out of the box solution. It requires configuration to meet your specific requirements. Our engineers have experience in designing and implementing systems from research & development through the manufacturing process that provide extremely accurate results. Talk with a solution expert about designing and implementing a Geometric Camera Calibration solution for your specific requirements.