Archives

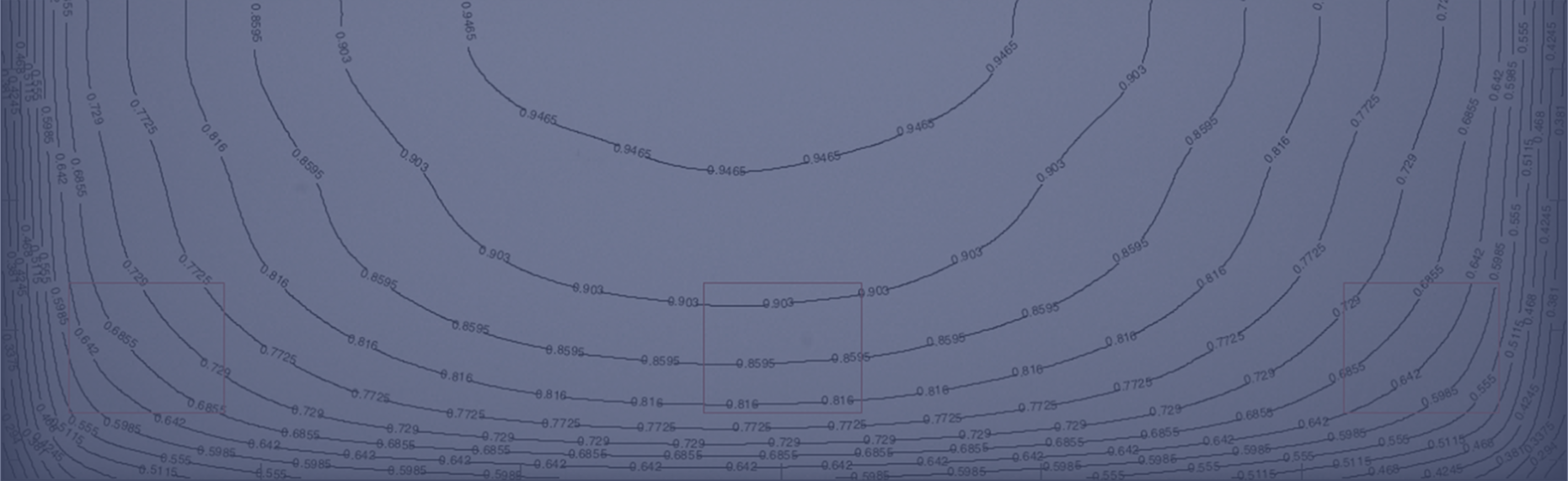

Imatest-Furonteer Geometric Calibration Solution

The Imatest-Furonteer Geometric Calibration Solution enables companies to understand the images captured from their devices. This solution calibrates as-built camera […]

Lightbox Comparison Guide

Lightbox Brightness Uniformity* CRI (spec.) Viewing Area Dimensions Controls ITI LED Lightbox 30 – 10,000 Lux 95.2% Over 97 […]

Imatest Studio

Your test lab is more than just a camera and software. Imatest offers more than just software for testing lenses […]

Gamutvision

Gamutvision™ is a color gamut viewer that allows you to explore the behavior of ICC profiles — files that characterize color spaces and/or […]

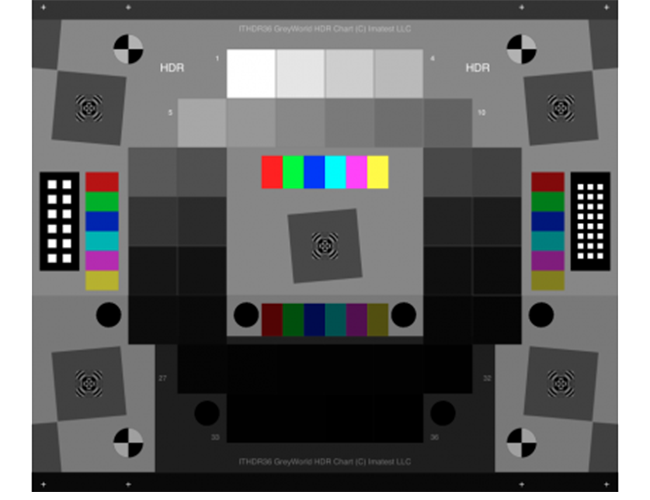

ISO Standard Test Charts

Manufactured to exacting standards Our ISO charts meet all ISO standards for image quality requirements on imaging devices.

SFRplus

Our in-house charts, designed by our team of experts, were specifically developed to work seamlessly with Imatest Master, IS and IT. SFRplus test charts are the most powerful charts available for imaging system development and quality verification.