Imaging systems designed to capture infrared light vary greatly depending on application. Some examples include the automotive and security industries as well as remote sensing and facial recognition. Imatest offers an array of targets that can be analyzed with Imatest Master and Imatest IT to provide statistics and metrics for accurate system benchmarking.

Targets

Near Infrared (720nm – 1100nm)

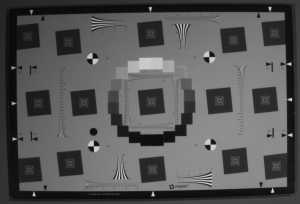

Near Infrared (NIR) charts can be produced on reflective and transmissive substrates. Inkjet targets work well in the NIR with some tonal adjustments made to compensate for contrast change in the longer wavelengths. Many of Imatest’s standard inkjet charts come with a NIR variant (ISO eSFR, Checkerboard, SFRplus, SFRreg, as well as custom designs). Charts can be tailored to specific spectral responses and common filter configurations such as systems centered at 850 or 940nm. Photographic prints (such as the Photographic ISO eSFR) also perform well in the NIR maintaining similar contrast.

Medium Wave Infrared (3 um – 5 um) & Long Wave Infrared (8 um- 15um)

Imatest offers two emissive SFRplus targets designed for longer wavelength testing. The MWIR SFRplus and LWIR SFRplus employ heating elements and thermally sensitive paints to create thermal contrast for slant edge MTF measurements in the Mid and Long wave infrared.

For custom designs please contact charts@imatest.com.

NIR Light Sources

Imatest offers a range of NIR LED light sources for NIR image quality testing. The Imatest LED Lightboxes and Light Panels can be configured with NIR LED channels for use with transmissive charts. The highly uniform Light Box can also be used for uniformity evaluation.

For reflective charts, Imatest offers a set of Metaphase NIR ExoLights. These commercial-grade light sources provide a dimmable range of NIR output for evenly illuminating even our largest reflective charts. They are fully compatible with the Reflective Module for the Imatest Modular Test Stand. This fixture can support both KinoFlo LED lights and Metaphase NIR ExoLights, allowing users to simultaneously test in both visible light and NIR.

Click on the images above to learn more about the individual light panels or reach out to us at sales@imatest.com.