Author: Henry Koren

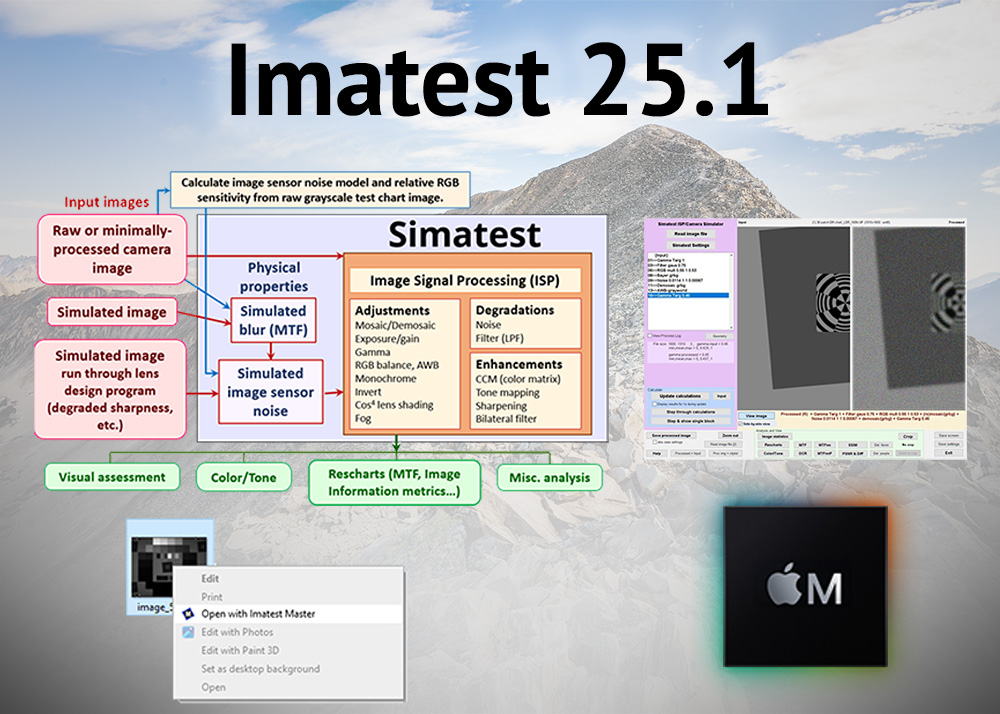

Imatest Releases Version 25.1

Simatest Camera & ISP Simulator, Open With Imatest, UI & Settings Improvements, Output Documentation

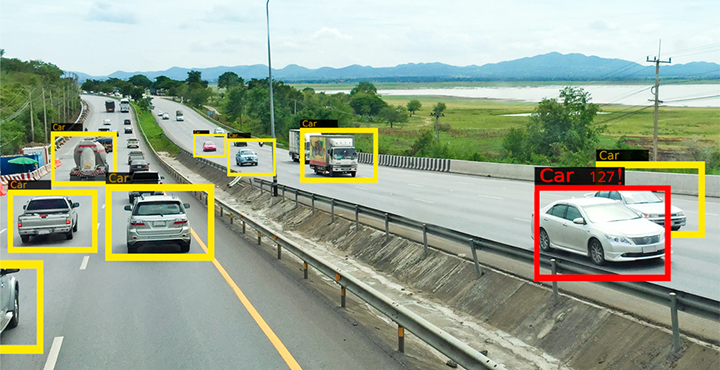

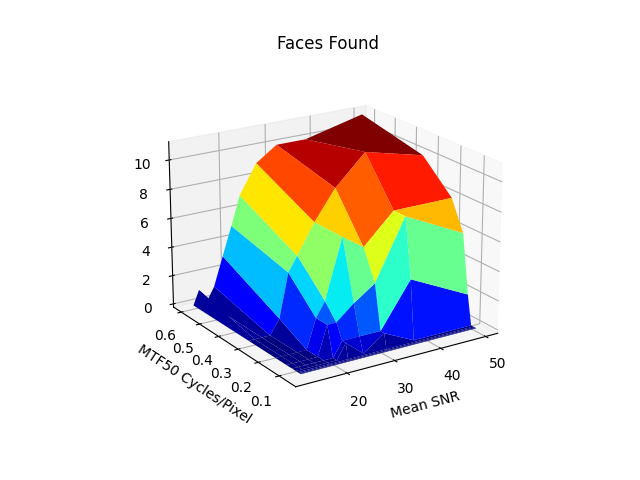

Validating Information Metrics Correlation with Object Detection

We are in the age of Artificial Intelligence that depends on machine vision. This technology surge has necessitated thinking about […]

Improving Image Equity: Representing diverse skin tones in photographic test charts for digital camera characterization

Megan Borek; Imatest LLC; Boulder, CO, USA This paper was presented on 2025-02-05 at Electronic Imaging 2025 Abstract: Accurate representation […]

2024 Year In Review

In 2024, Imatest greatly increased our image quality testing capabilities with significant advancements across software, hardware, charts, and solutions. We […]

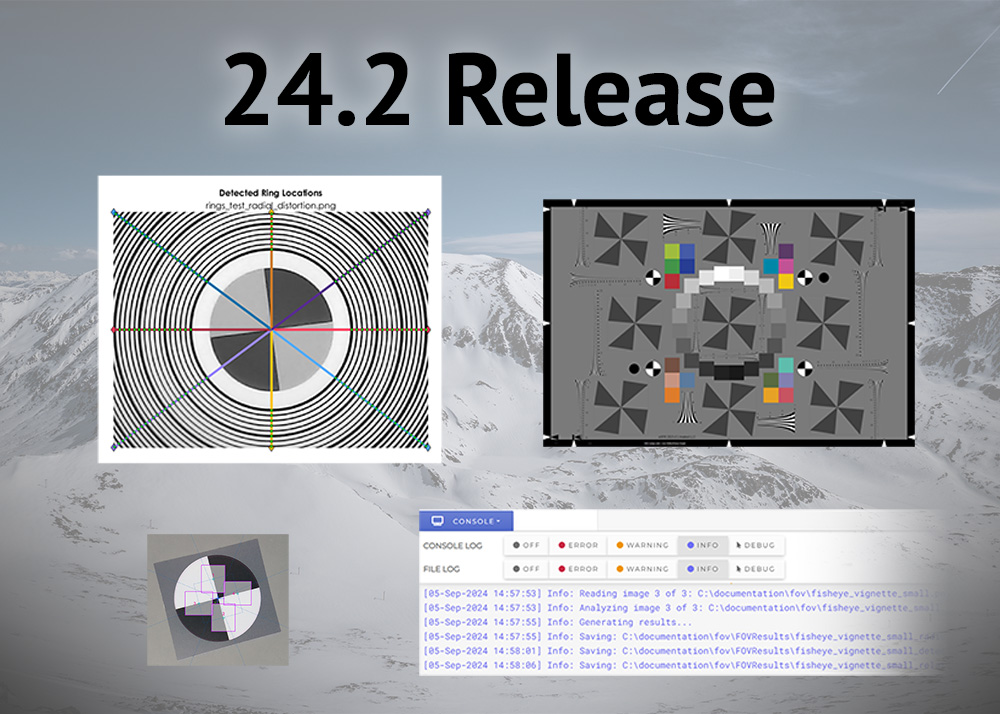

Imatest releases version 24.2

Concentric ring FOV, ISO Sharpness target support, batch folder processing, console panel, macOS Sequoia

Imatest 20th Anniversary

Imatest was founded by Norman Koren in Boulder, Colorado, in 2003. On September 4th 2004, we sold our first Imatest 1.0 licenses. […]

AutoSens Europe 2024

Join us and other automotive imaging industry experts on October 8-10 in Barcelona, Spain. We will present our advanced testing methods and algorithms […]

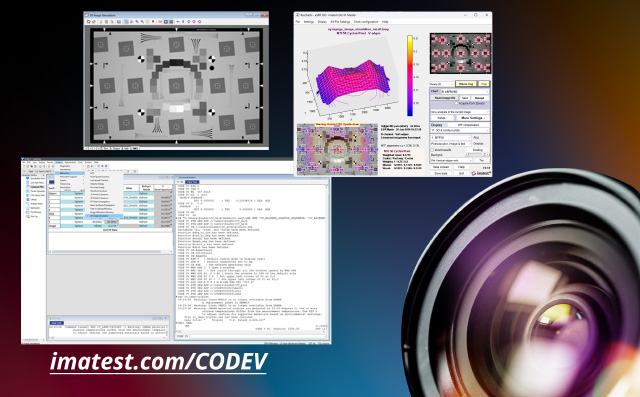

Using Imatest with CODE V 2D Image Simulation (IMS)

Imatest test charts raster files and can be used with 2D Image Simulation (IMS) to create images with the degradations […]

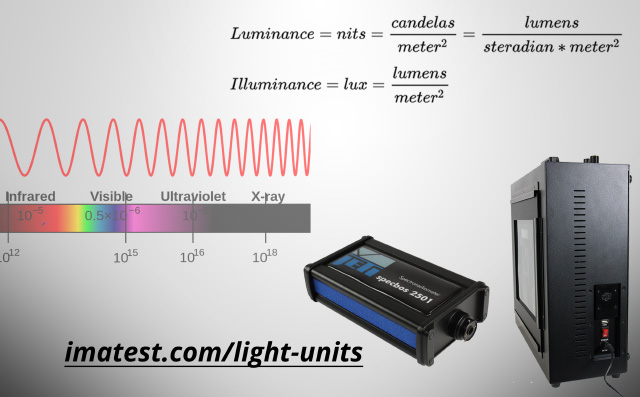

Photometry Luminance and Illuminance units vs. Radiometry Radiance and Irradiance units

This knowledge base post describes why lightboxes are traditionally described in photometric illuminance units of Lux, despite a more appropriate […]

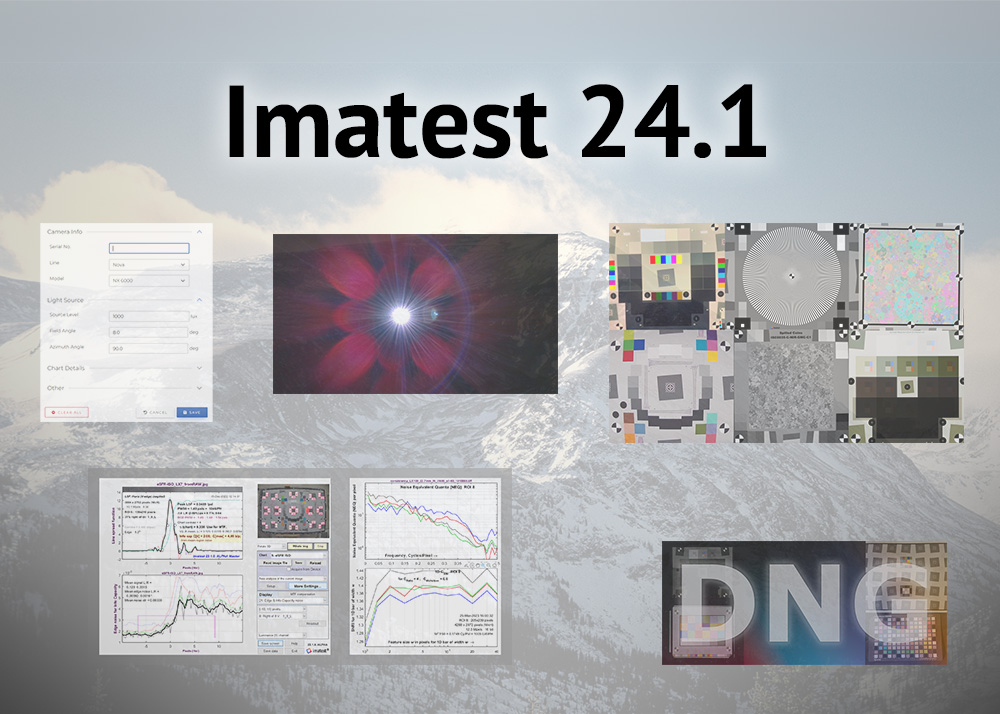

Imatest release new version Imatest 24.1

Custom Metadata, Edge Informatiom Metrics, DNG improvements, Stray Light improvements & Registration Mark Detection.

Imatest Presented at AutoSens USA 2024

Leader SFR-Fit MTF Measurement Software SFR-Fit is camera resolution measurement software that measures MTF (Modulation Transfer Function). MTF indicates spatial […]

Imatest Electronic Imaging 2024 Recap

Have a virtual visit to our booth and read the papers we published to advanced imaging science.

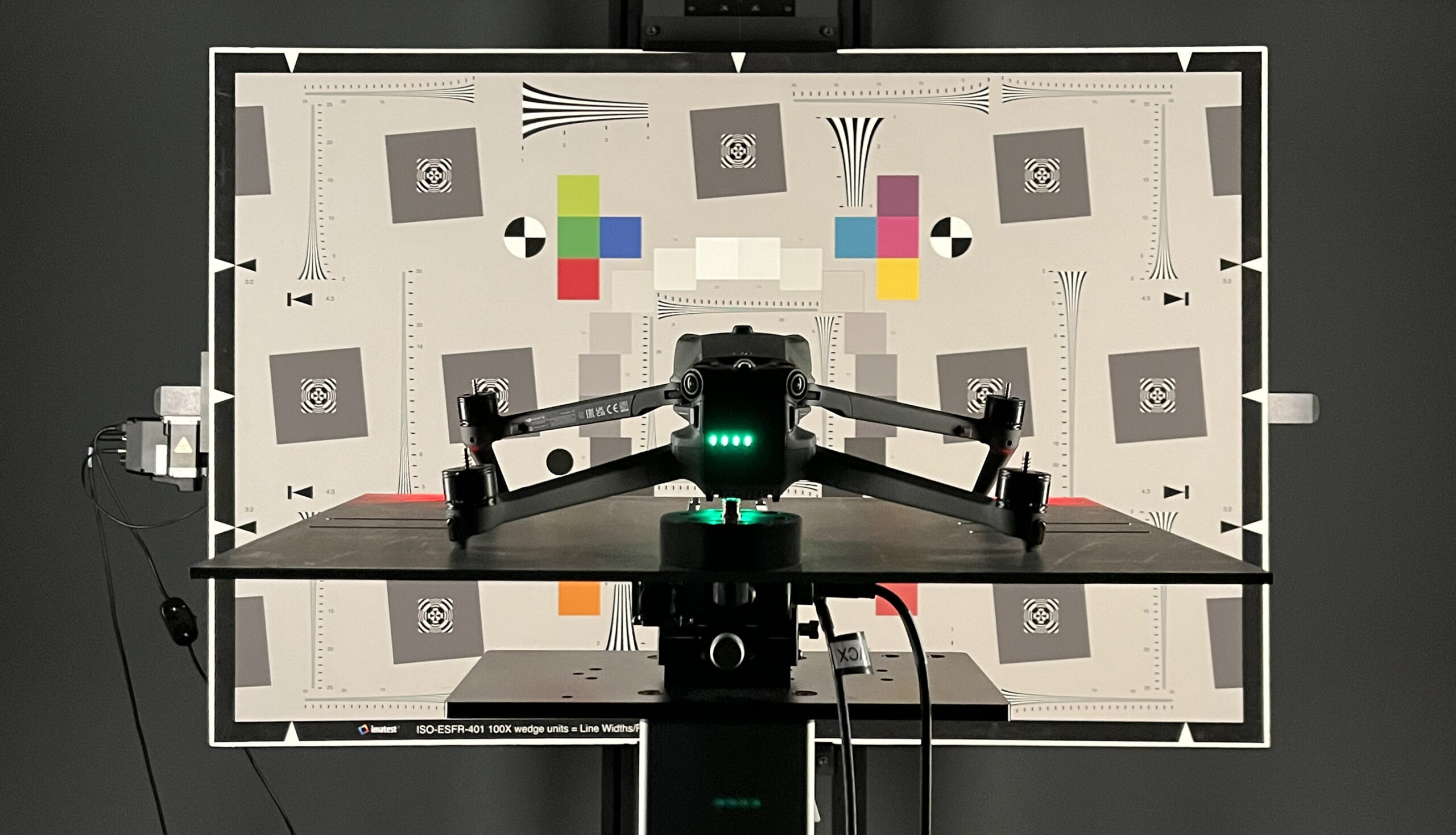

Test Lab Services Drone Comparison

Skydio reached out to Imatest for an independent, objective comparison of different manufacturers’ drones. Our focus was on critical aspects […]

2023 Imatest Year in Review

This year has been a milestone for Imatest. We’ve introduced an array of innovative products, software, and services, thanks to […]

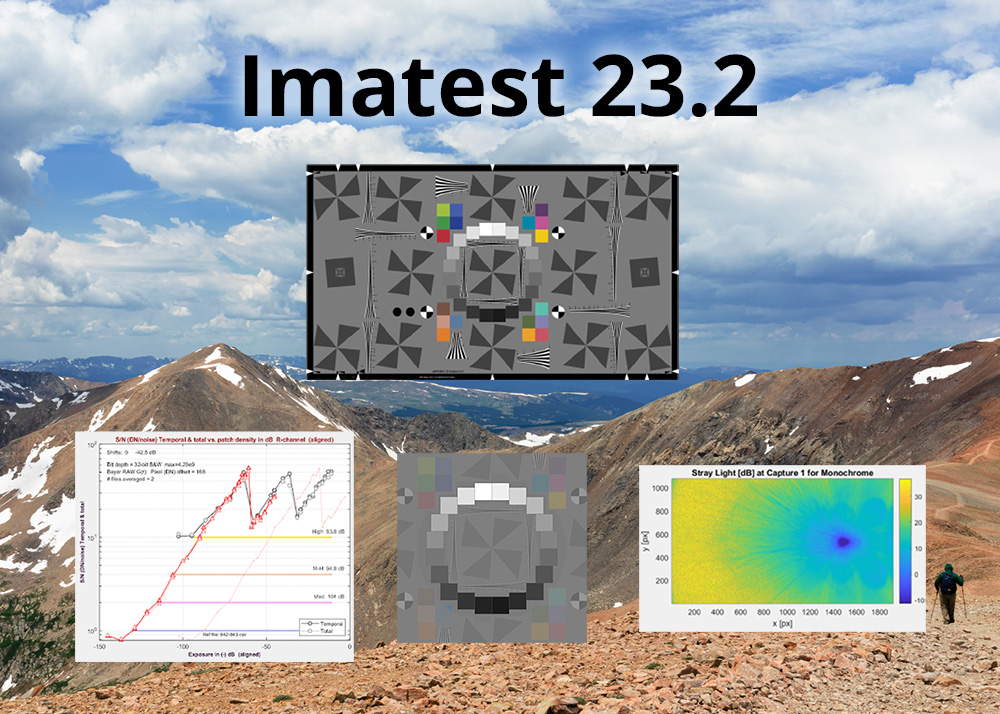

Imatest release new version Imatest 23.2

Including support for the 2023 “slanted star” revision of the ISO 12233 resolution standard, improved stray light, and improved dynamic […]

Uniform Reflectance Targets

These targets provide spectrally neutrality and diffuse Lambertian reflectance for camera uniformity testing. Available in a range of sizes for […]

Virtual Visit to Imatest’s Booth at Autosens Brussels 2023

At Autosens Brussels 2023, Imatest demonstrated the Imatest Benchtop Test Stand-Stray Light/Target Projector Version. Norman Koren, founder of Imatest, presented […]

Call for Participation in Perceptual Image Quality Research

The IEEE P1858 standard for Camera Phone Image Quality has produced two revisions of its Camera Phone Image Quality (CPIQ) […]

Correlating the Performance of Computer Vision Algorithms with Objective Image Quality Metrics

by Henry Koren 1. Why care about the quality of your cameras? The task of computer vision (CV) involves analyzing […]