Author: Imatest Admin

Imatest Founder Norman Koren Receives Lifetime Achievement Award

Imatest LLC Chief Technical Officer and Founder Norman Koren was awarded a Lifetime Achievement Award by AutoSens during the latest AutoSense-Detroit.

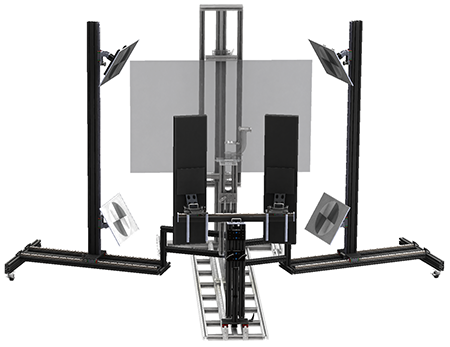

Imatest Announces the WFOV Module

Imatest introduces its new Wide Field of View (WFOV) Module, which is an easy-to-use platform for testing sharpness in cameras […]

Image Quality Testing for Webcams

Webcams are an increasingly vital tool for working remotely and staying connected with friends and loved ones. As such, webcam […]

Imatest Asia Pacific Remote Training

Imatest is offering a two-day training course to professionals using or considering Imatest software to improve their image quality testing […]

Imatest Training Schedule

2021 Class Schedule:

March 24-25, 2021: Americas

English; Mountain Time

April 21-22, 2021: Europe

English; Central European Time

May 12-13, 2021: Asia Pacific

English & Mandarin; China Standard Time

September 21-22, 2021: Americas

English; Mountain Time

October 12-13, 2021: Korea

English & Korean; Korea Standard Time

November 11-12, 2021: Asia Pacific

English & Mandarin; China Standard Time

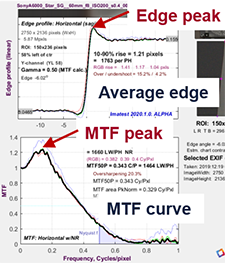

Correcting Misleading Image Quality Measurements

We discuss several common image quality measurements that are often misinterpreted, so that bad images are falsely interpreted as good, and we describe how to obtain valid measurements.

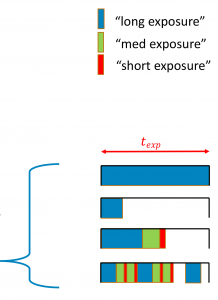

Describing and Sampling the LED Flicker Signal

High-frequency flickering light sources such as pulse-width modulated LEDs can cause image sensors to record incorrect levels. We describe a […]

Validation Methods for Geometric Camera Calibration

Camera-based advanced driver-assistance systems (ADAS) require the mapping from image coordinates into world coordinates to be known. The process of computing […]

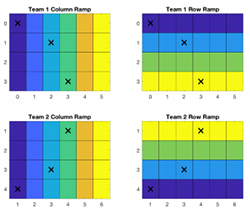

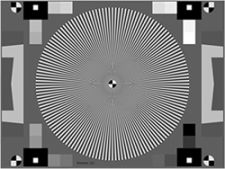

Measuring camera Shannon information capacity with a Siemens star image

Shannon information capacity, which can be expressed as bits per pixel or megabits per image, is an excellent figure of […]

Verification of Long-Range MTF Testing Through Intermediary Optics

Measuring the MTF of an imaging system at its operational working distance is useful for understanding the system’s use case […]

Imatest Releases Version 2020.1

Imatest, a global image quality testing solution provider, is pleased to announce Imatest 2020.1 that adds new features on top […]

Imatest Addresses Coronovirus

Imatest Customers and Partners, As the COVID-19 coronavirus continues to spread, the health and safety of our team, community, customers […]

Imatest EI Presentations Now Online

The research papers presented at this year’s Electronic Imaging Symposium (EI 2020) by Imatest engineers are now available.

Imatest Announces the New Collimator Fixture

Imatest introduces its new Collimator Fixture, which can test your imaging system at distances up to infinity — all within […]

Imatest Announces the new MTS Reflective Module

Imatest is now offering the MTS Reflective Module, which is an add-on to the Imatest Modular Test Stand. The easy-to-use […]

Imatest is Attending Electronic Imaging 2020

Imatest is attending Electronic Imaging 2020 in Burlingame, California on January 26-30, 2020. The symposium brings together 17 technical conferences covering […]

Imatest will be at SPIE Photonics West 2020

Imatest is attending and exhibiting at SPIE Photonics West in San Francisco, February 1-6, 2020.

San Jose, CA Imatest Training Course – November 6-7, 2019

Imatest representatives will visit San Jose, CA, November 6-7, 2019, to offer a paid two-day training course to professionals using or considering Imatest software to improve their image quality testing processes.

Imatest Support Renewal

Maintaining current support on your Imatest license allows you to access all new version releases and updates during the support […]