Author: Imatest Admin

MATLAB Runtime Update 5 or greater required by Imatest 5.2

Imatest 5.2 depends on the MATLAB Compiler Runtime (MCR) version 2019a (also known as v96), specifically Update 5 or later. […]

Introducing Imatest 5.2

BOULDER, CO -September 12, 2019—Imatest, a global image quality testing solution provider is pleased to announce Imatest 5.2. With this […]

Imatest and Furonteer Collaboration Finalist for Best Validation/Simulation Tool Award

BOULDER, CO -September 4, 2019—Imatest, a global image quality testing solution provider, and Furonteer, an automation equipment manufacturer, are finalists […]

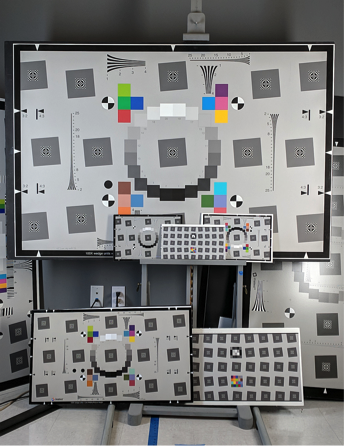

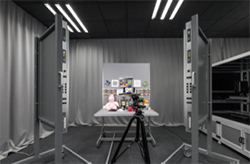

Imatest Announces Modular Test Stand

Boulder, Colorado, August 30, 2019—Imatest, a global provider of image quality testing solutions, now offers a Modular Test Stand (MTS) […]

AutoSens Brussels, September 17-19, 2019

Imatest will attend AutoSens in Brussels on September 17-19, 2019. AutoSens is a 3-day workshop, conference, and exhibition advancing the […]

Imatest won’t launch on Mac OS (Catalina, Mojave)

For users of Mac OS Catalina Due to incompatibility with MATLAB runtimes in older releases. Please note that Catalina is […]

July 2019 Newsletter

Our newsletter features our products, company news, educational image quality articles, Imatest events, and relevant industry articles. Subscribe to receive […]

June 2019 Newsletter

Our newsletter features our products, company news, educational image quality articles, Imatest events, and relevant industry articles. Subscribe to receive […]

Imatest and Furonteer Reduce Camera Intrinsic Calibration Time with Automated Machines

BOULDER, CO – JUNE 25TH, 2019 — Imatest, a global image quality testing solution provider, partnered with Furonteer, an automation […]

Shanghai, China – Imatest Training Course – November 11-12, 2020

Imatest in Shanghai Imatest engineers will visit Shanghai, China, November 11-12, 2020, to offer a paid two-day training course to […]

Seoul, South Korea – Imatest Training Course – October 20-21, 2020

Imatest in Seoul Imatest engineers will visit Seoul, October 20-21, 2020, to offer a paid two-day training course (October 20-21) […]

San Jose, CA – Imatest Training Course – August 6-7, 2020

Imatest in San Jose Imatest engineers will visit San Jose, California between August 6-7, 2020 to host a paid two-day […]

Germany – Imatest Training Course – March 24-25, 2020

Imatest engineers planned to visit Germany on March 24-25, 2020 to host a paid two-day training course to professionals using or considering Imatest software to improve their image quality testing processes.

In light of the COVID-19 Coronavirus, this training course will be held remotely.

Imatest will Attend AutoSens Detroit on May 14-16, 2019

Imatest will attend AutoSens in Detroit on May 14-16, 2019. AutoSens is a 3-day workshop, conference, and exhibition advancing the […]

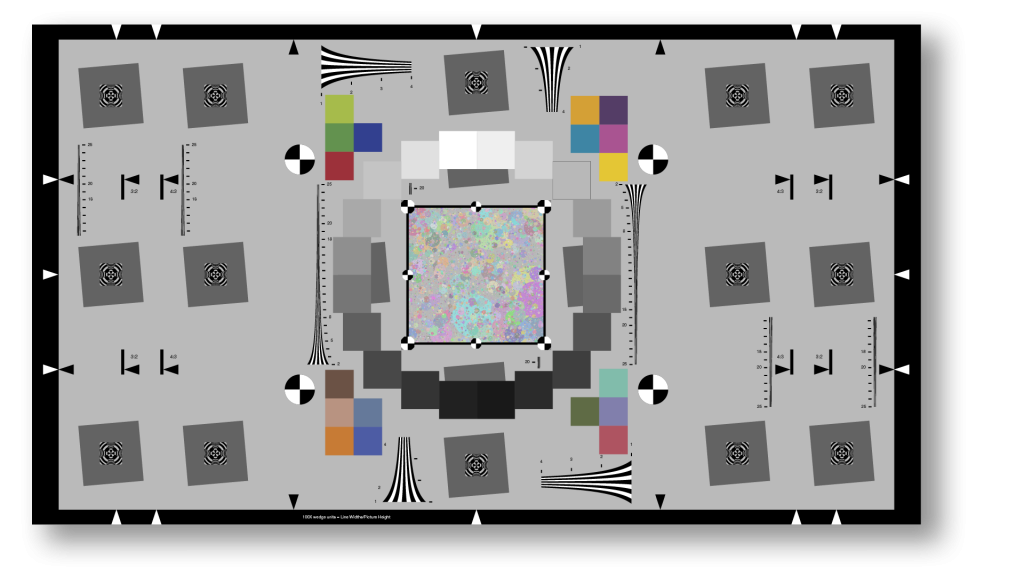

Using Arbitrary Charts for Development of the P1858 Variation Combo Chart

The release of Imatest 5.0 introduced a number of powerful new features, including the Arbitrary Charts module which enables Imatest […]

Compensating MTF Measurements for Chart Quality Limitations

Camera MTF (sharpness) measurements are subject to a number of variations, some of which, like noise, are random and difficult […]

Imatest Branded Lightboxes and Light Panels

We are pleased to announce that beginning January 2019, we are offering Imatest branded light panels and boxes. Imatest has […]

Partnership with Shenzhen Polytechnic University

Imatest partnered with Shenzhen Polytechnic University to support the digital image quality testing curriculum at the university. With the expansion […]

Electronic Imaging Symposium 2019

Join Imatest at the Electronic Imaging Symposium from Jan. 13 – 17 in Burlingame, California USA. Explore the entire imaging […]

December 2018 Reading List

Our team has outlined a list of our favorite imaging resources that we use on the job here at Imatest. […]