Imatest Customer Profile: Dan Bennis

Mia: Can you tell me about your current role? Dan: I’m a systems engineer at Precision Optics Corporation (POC). […]

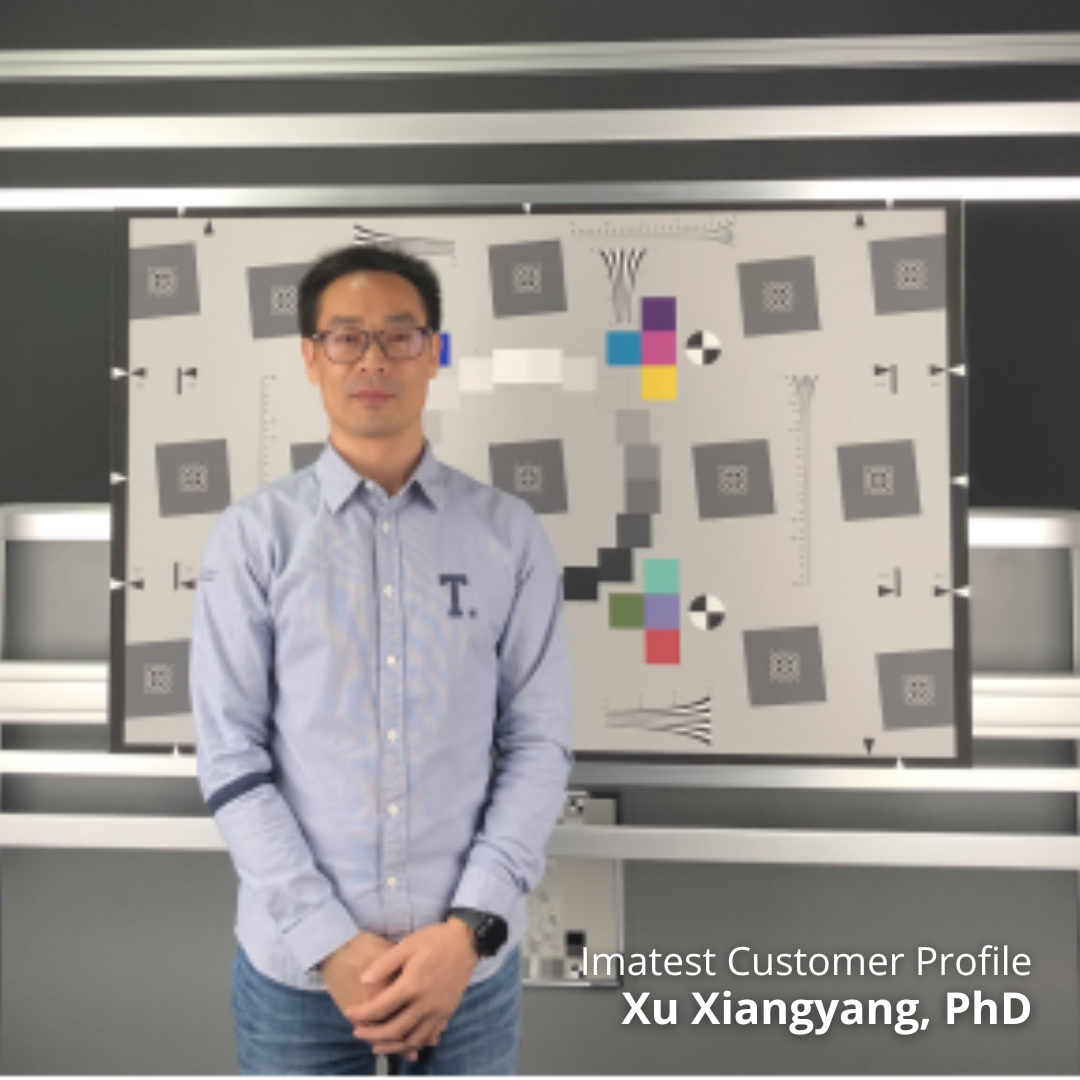

Imatest Customer Profile: Professor Xu Xiangyang, PhD

Q: Mr. Xu, what kind of work do you do? A: I am currently working as a professional teacher in […]

Imatest Customer Profile: K. Tina Agnes Ruth

Mia What do you do for work? Tina I am an Imaging engineer at E-con Systems. At E-con Systems we […]

Imatest Customer Profile: Russell Bondi

Mia Could you go into detail about what you do for work? Russ Yes, I’m an image quality engineer at […]

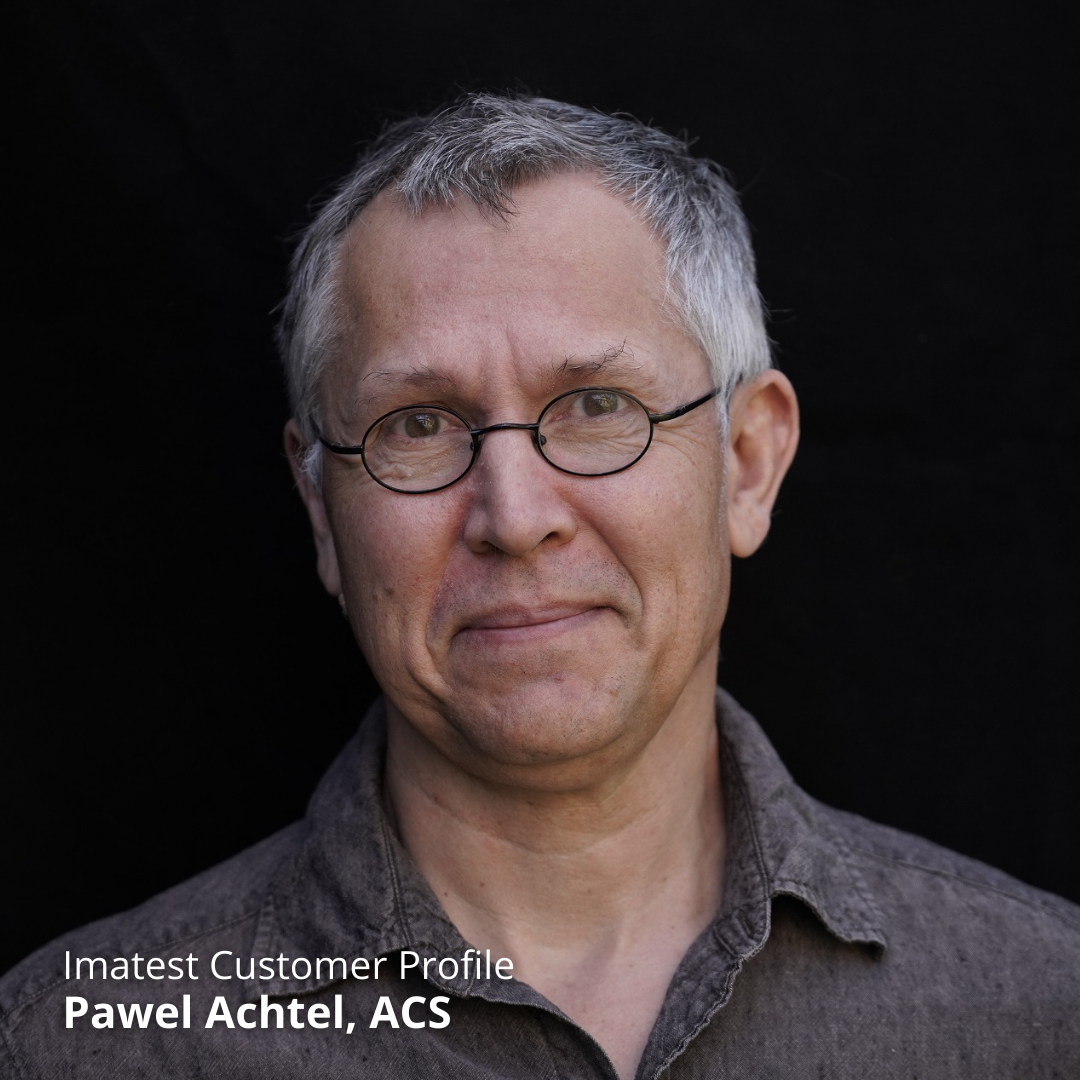

Imatest Customer Profile: Pawel Achtel, ACS

This month, we have a very special customer profile. We had the chance to chat with Pawel Achtel, a cinematographer […]

Imatest Customer Profile: Naveen Koul

Mia: The first question is what do you do for work? Naveen: I’m an image quality engineer. I work mainly […]

Imatest is Partnered with Edmund Optics

Imatest is proud to announce a new partnership with Edmund Optics. You can visit Edmund Optics Silicon Valley Solutions Center […]

Imatest Customer Profile – Dr. Brian Deegan

Imatest is happy to introduce customer profiles! Each month, we will interview one of our Imatest users to share why […]

Using images of noise to estimate image processing behavior for image quality evaluation

In the 2021 Electronic Imaging conference (held virtually) we presented a paper that introduced the concept of the noise image, […]

Imatest macOS package installer “can’t be opened because Apple cannot check …”

To resolve this issue in macOS, open System Preferences:Security&Privacy and in the General tab give permission to open the installer. […]

Imatest Announces the WFOV Module

Imatest introduces its new Wide Field of View (WFOV) Module, which is an easy-to-use platform for testing sharpness in cameras […]

Imatest EI Presentations Now Online

The research papers presented at this year’s Electronic Imaging Symposium (EI 2020) by Imatest engineers are now available.

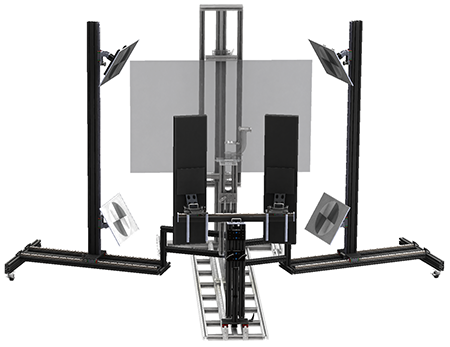

Imatest Announces Modular Test Stand

Boulder, Colorado, August 30, 2019—Imatest, a global provider of image quality testing solutions, now offers a Modular Test Stand (MTS) […]

July 2019 Newsletter

Our newsletter features our products, company news, educational image quality articles, Imatest events, and relevant industry articles. Subscribe to receive […]

June 2019 Newsletter

Our newsletter features our products, company news, educational image quality articles, Imatest events, and relevant industry articles. Subscribe to receive […]

Shanghai, China – Imatest Training Course – November 11-12, 2020

Imatest in Shanghai Imatest engineers will visit Shanghai, China, November 11-12, 2020, to offer a paid two-day training course to […]

Seoul, South Korea – Imatest Training Course – October 20-21, 2020

Imatest in Seoul Imatest engineers will visit Seoul, October 20-21, 2020, to offer a paid two-day training course (October 20-21) […]

San Jose, CA – Imatest Training Course – August 6-7, 2020

Imatest in San Jose Imatest engineers will visit San Jose, California between August 6-7, 2020 to host a paid two-day […]